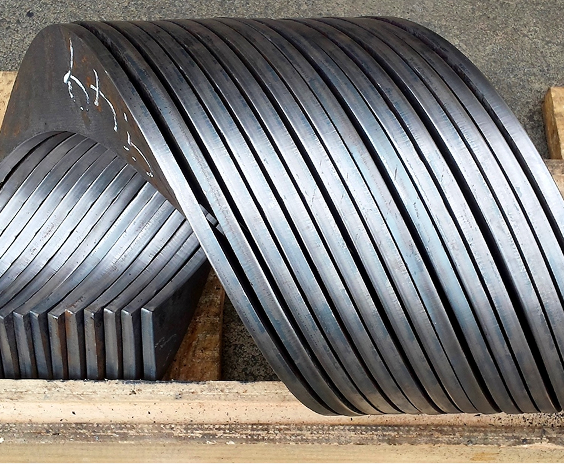

Sectional Flighting

Precision Flighting for Critical Applications

At Artisan Precision Mfg. LLC, we deliver True Form sectional flights with consistent accuracy and precision. Our in-house fabrication process guarantees tight tolerances, and allows us to offer expedited delivery times for your critical applications.

Using advanced Flight Forming technology and Blank Cut Design Software, we calculate precise blank profiles before forming—minimising waste and ensuring pitch uniformity within 0.5°. The result? Precise fit, reduced assembly time, and a superior product.

Why Choose Our Sectional Flighting?

- Precision: Exact blank geometry for perfect fit.

- Size Flexibility: Custom pitch, diameter, thickness, and material.

- Material Versatility: Carbon Steel, Mild Steel, Stainless Steel, Hardox.

- Design Options: Cut & Fold, Tapered Diameters, Progressive Pitch, Canted, Cupped Flights.

- Expedited Delivery: Quick turn-around production for urgent projects.

- True Form Reliability: Consistent geometry for efficient welding and installation.

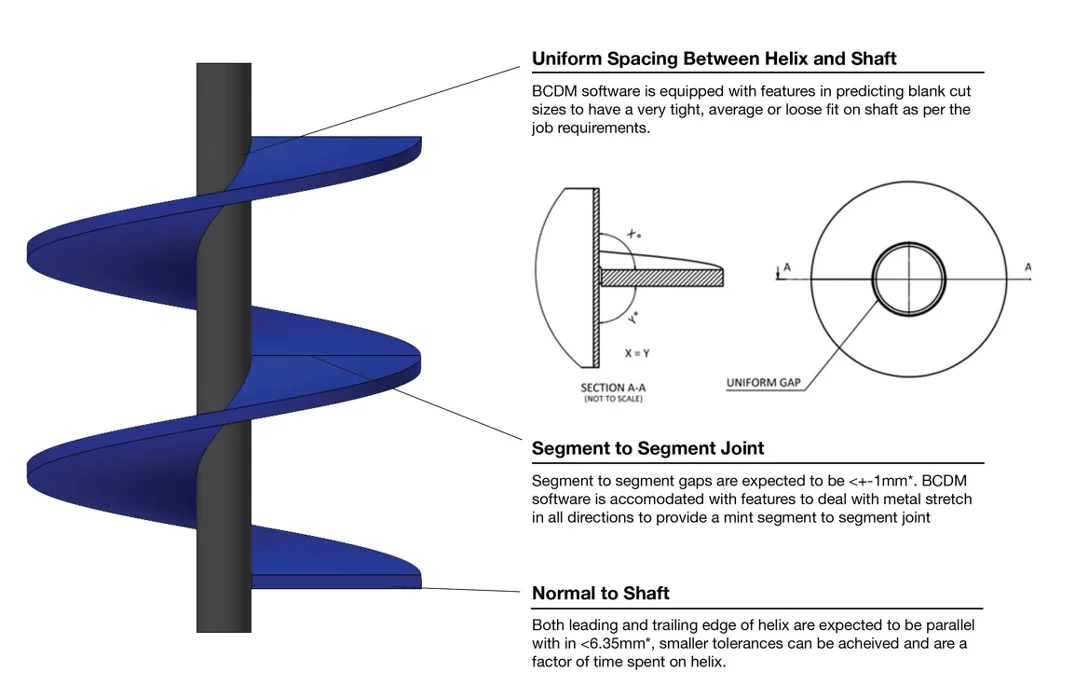

What do we mean by True Form Helix? Precision & Performance

A True Form Helix is engineered for perfect geometry:

1. The flange sits at 90° to the shaft.

2. The internal edge remains parallel to the shaft.

3. A consistently uniform pitch angle is maintained throughout

Key Benefits:

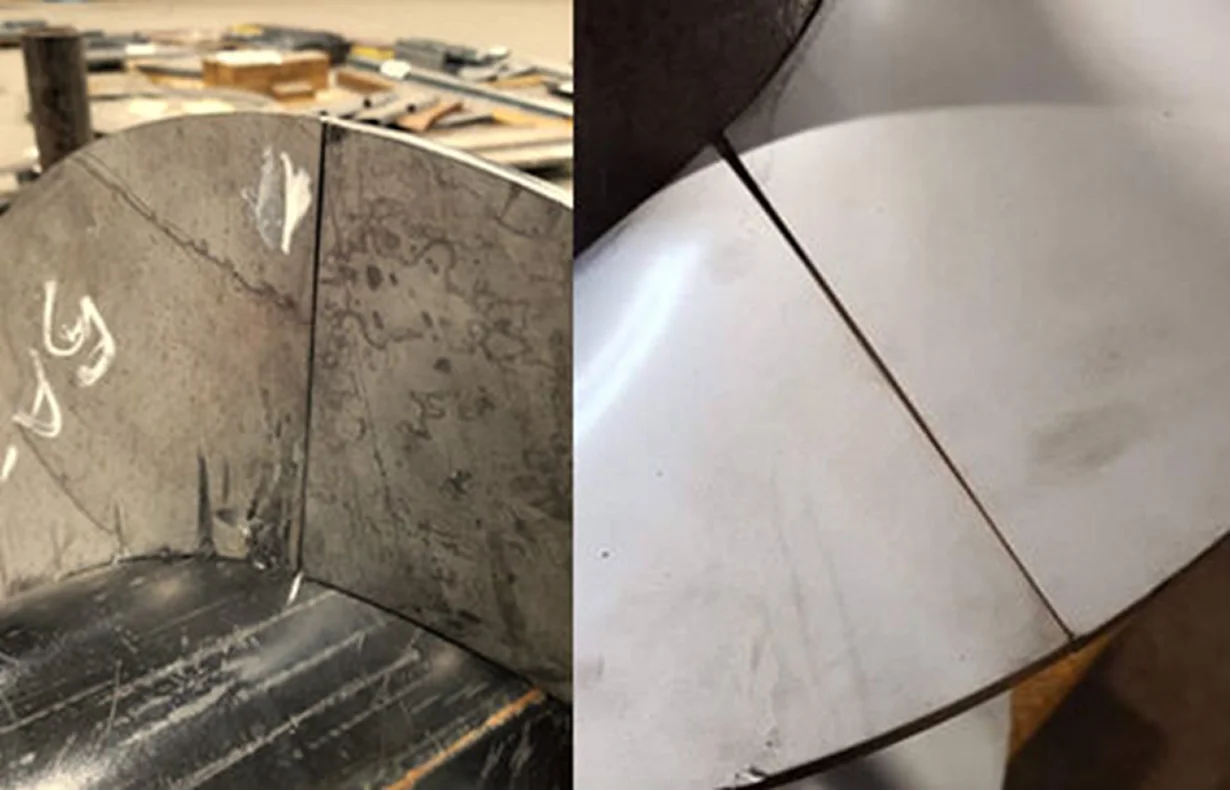

Exceptional Fit & Efficiency: Snug, secure fit eliminates secondary operations like grinding or cutting.

Consistent Welding Quality: Parallel internal edges ensure uniform weld roots for stronger joints.

Faster Assembly: Precise fit reduces rework and speeds up production

By choosing True Form Helices, you achieve reliable performance, improved handling efficiency, and superior results in every application

Industries We Serve

Agriculture: Grain, seed, fertiliser handling

Food & Beverage: Dry goods processing and mixing

Biomass & Renewable Energy: Pellet and feed systems

Waste & Recycling: Light-duty augers for compactors

Water Treatment: Sludge

handling

Chemical & Pharmaceutical: Powder dosing and mixing

Light Industrial Manufacturing: Plastics, powders, small aggregates

Core Applications

- Screw Conveyors & Augers – powders, grains, pellets, light aggregates

- Feeders & Dosing Systems – precise material flow control

- Mixing Equipment – industrial mixers for food, chemicals, plastics

- Agricultural Augers – seeders, grain handling, fertiliser spreaders

- Biomass Feed Systems – pellet and boiler feed screws

- Food Processing Equipment – hygienic conveying and mixing

- Waste & Recycling Augers – shredders and compactors

- Water Treatment Systems – sludge and grit removal

- Chemical & Pharmaceutical – powder dosing and mixing

Ready to Get Started?

Contact Us Today to discuss your sectional flighting requirements.